It is often overlooked or considered less important than it really is. Very often you go to look for the cause of the engine malfunction who knows where, when everything can simply depend on her: the candle.

Although it is a seemingly simple element, the candle plays, in fact, a fundamental role in the engine, as the main organ of the ignition system. It is entrusted with the task of burning the compressed air-gasoline mixture, triggering the combustion that will then have to propagate inside the combustion chamber. This is done thanks to the release of a spark between two electrodes, with a process, in principle, absolutely similar to that that occurs daily in the ignition of any gas cooker. Clearly, the conditions in which this happens are decidedly different and the ignition is also favored by the fact that the mixture, due to the situations present in the cylinder, reaches a considerable temperature and pressure.

Let us then see in detail how it works. In order for the spark to jump from one point to another of the two electrodes (generally divided into one internal and another external), the current voltage must be very high, that is,

Technology, today, often integrates coils into candle pipettes (which is impossible in Desmodue, however, since a considerable depth of candle wells is required).

Whatever the position of the coil, the candle, on the other hand, is always there, at the head of the engine, accessible laterally on the Desmodues and centrally on the Desmoquattro.

If we want to analyze its anatomy, let’s imagine it dissected along a longitudinal plane.

We will find it, commonly, formed by a metal body crossed by a steel rod (thecentral electrode),isolated from the rest with a porcelain casing, also visible from the outside. At 0.5-0.7 mm from its tip is placed another electrode, connected instead to the metal body(mass electrode). Clearly, the distance between the two is of fundamental importance for the proper functioning of the complex. On the body there is a thread that serves to secure the candle to the head of the engine, equipped with a special metal seal, suitable to ensure a perfect compression seal.

For normal operation of the system, electrodes must always be between500° and 800° in temperature. A lower temperature, in fact, would soon lead to smearing (and non-operation), while an excessive temperature would cause damage to the electrodes, leading to self-ignition (if the electrodes were to become glowing, for example, the mixture would certainly not wait for the spark to ignite! We would have the formation of a so-called “hot spot”, with the consequent disphasing of the ignition compared to the intended point).

Therefore, the candle also plays another rather important role: that of heat exchanger. It is entrusted with the removal of excess heat from the blast chamber, to a greater or lesser extent depending on its thermal degree. This depends, to a large extent, on the geometric and constructive characteristics of the electrodes and insulation.

Depending on the specific qualities of the engine, these elements must be configured in such a way as to always guarantee an optimal operating temperature, through the disposal of heat accumulated during combustion.

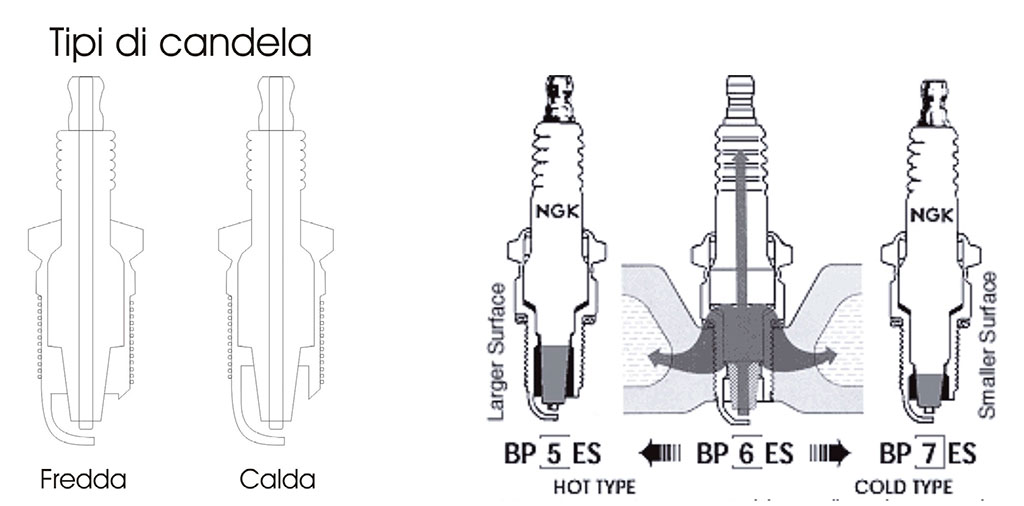

Motorcycle candle: hot or cold

That is why, in the common nomenclature, the term “hot” candles and “cold” candles is used: the former are used in less sporty engines, poorly compressed and reaching a low number of revolutions, i.e. lower temperatures; the latter are used, on the other hand, in the most performing motors, with high compression ratios, able to turn at higher speeds (and which, consequently, heat more).

To understand how these two types differ, just observe the fact that a “cold” candle has a lower exposed surface of the insulation than a “hot” one (which, therefore, will ensure slower heat removal).

To get maximum performance from the engine it is necessary to make the mixture burn completely,in any situation, and this depends precisely on the good functioning of the candles. In addition, especially in large-volume twin-cylinder engines, there is a risk that the flame front, due to the high begging, completes its path too slowly, or even that unburned mixture residues remain at the time of expansion of the piston. For this reason, as in 1000 and

1100 DS, double

ignition is used, that is, the adoption of a second candle for each cylinder, to guarantee complete and more efficient combustion.

Even in motors equipped with a single candle it is evident that it is advisable to mount suitable type candles in terms of thermal degree, distance between the electrodes and thread length, as prescribed by the manufacturer.

Saving on candles would result in a waste of gasoline and a decrease in performance such that… the game wouldn’t be worth the candle!

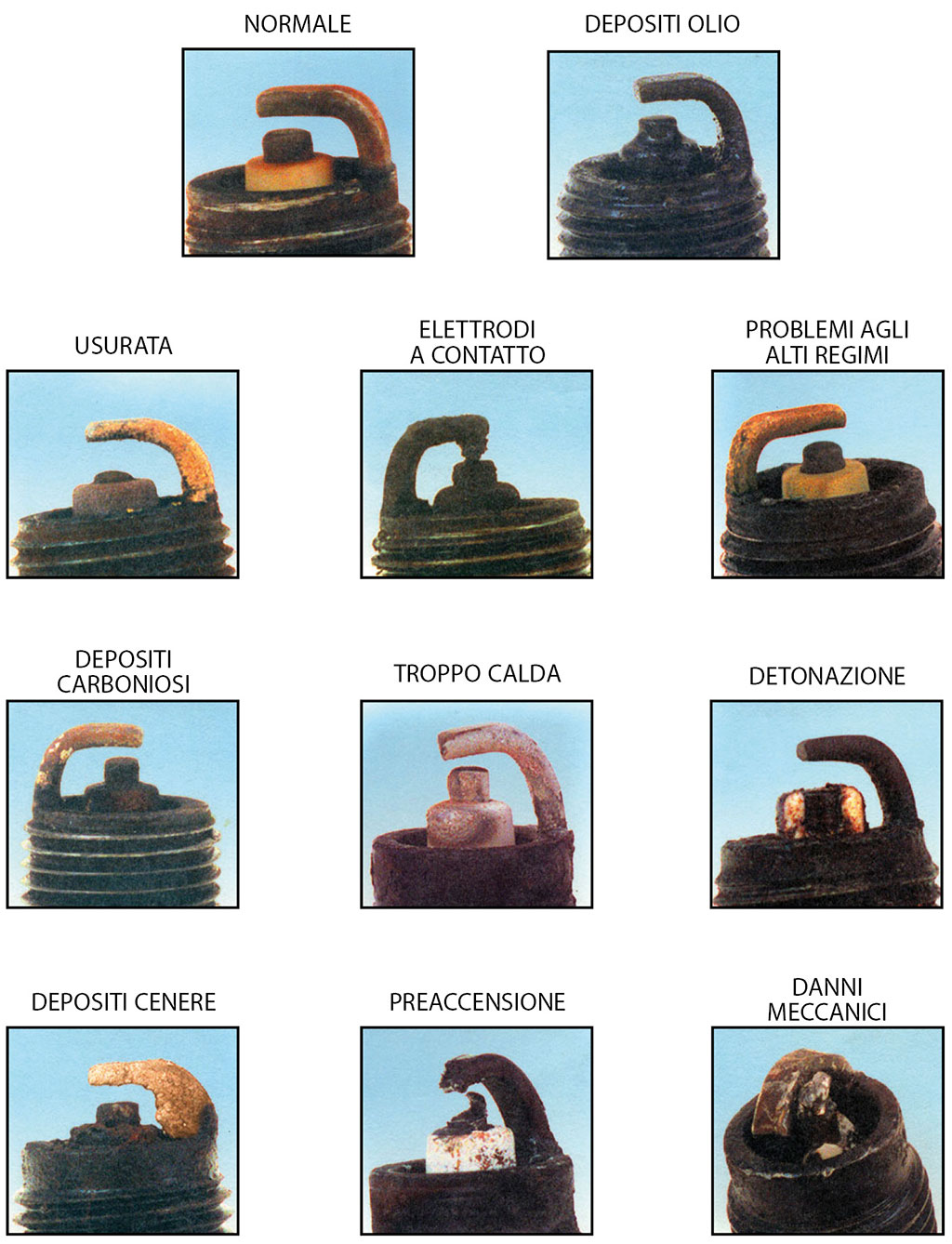

Puns aside, it is essential above all to carry out their proper maintenance, through scrupulous periodic checks. The candle is, in fact, a spy of the operation of the engine, since from its apparent condition we candeduce the state of health of the engine .

First of all, it is necessary to follow some simple precautions in the disassembly and reassembly of this essential component.

All candles have a hexagonal nut, but this can be of different sizes, depending on the type of candle or depending on the manufacturer. It will then be advisable to be equipped with the different types of keys (the best are those equipped with a ratchet or joint graft). Disassembly should never present problems, while during reassembly it is necessary to pay close attention to the presence of impurities on the thread or near the hole on the head, to avoid “polluting” the combustion chamber.

We also remember that the candle must always be screwed by hand until the gasket is beaten (if it is new); after that we can tighten it with the key, possibly also using a dynamometric, tothe torque provided by the manufacturer.

Motorcycle candle: read the engine signals

How can we really interpret what the candle can communicate? To have a reliable reading it is preferable to take, before disassembly, a stretch of free and fast road, so that the engine works in optimal conditions and you do not have a false reading. Once disassembled, we will be able to assess the “health” of the thruster.

Thus, if we look at the electrodes we will notice carbonaceousresidues, this will be a sign of too low combustion temperatures or too rich a mixture; or, incomplete combustion may averse due to an excessively delayed spark or insufficient intensity. Oil-smeared electrodes, on the other hand, herald disaster, since they are a symptom of poor tightness of the bands, now consumed, or worn valve guides. It is also important to observe the color of the ceramic insulation at the foot of the electrodes themselves: a white or beige coloring indicates that the candle is too hot or, if we are sure that it is the right one, that the mixture is too thin. Conversely, if it is very dark, blackish,the mixture is oily or, possibly, the candle is too cold. The right color, of course, must be a middle ground, something similar to light hazelnut color,and it is evident that different readings on the two cylinders will be the obvious indication of a malfunction.

Another important chapter is the electrodes: if the engine hardly starts cold or loses shooting and accelerating shots, we can rest assured that the electrodes have worn out or, worse, that the insulation has deteriorated.

To stem the problem, it is enough to restore the correct distance between the electrodes via a thickemeter or, better than ever, proceed to replace the candles before they are reduced… to the light.

SBK a Jerez: avanti tutta!

A Jerez de la Frontera, seconda tappa del campionato SBK, si ri-accende lo spettacolo con Ducati protagonista. Doppietta di Redding e secondo posto in gara 2 per Davies.

Bicilindrico a “L” Ducati: i motivi del successo

Analizziamo i motivi del successo della caratteristica architettura dei bicilindrici Desmo, nata per esigenze di raffreddamento e consolidata negli anni.